At Smiths, our technology and innovation benefit millions of people every day – making travel safer, supporting global decarbonisation, efficiently heating and cooling our homes, and making our world better connected.

A history of innovation

1851

Samuel Smith opens his first jewellery shop in south London, founding the business that will later become Smiths Group.

1904

Smiths innovates with the early development of car speedometers, fitting one to King Edward VII’s Mercedes.

1912

A Smiths speedometer is adapted as a sledge-meter for Captain Scott’s epic expedition to the South Pole.

1919

World’s first direct transatlantic flight takes place in a Vickers Vimy bomber fitted with Smiths instruments, taking over 16 hours.

1939

Smiths supports the war effort, producing over 10 million aircraft instruments, 4 million clocks and 1.5 million speedometers and mileage counters.

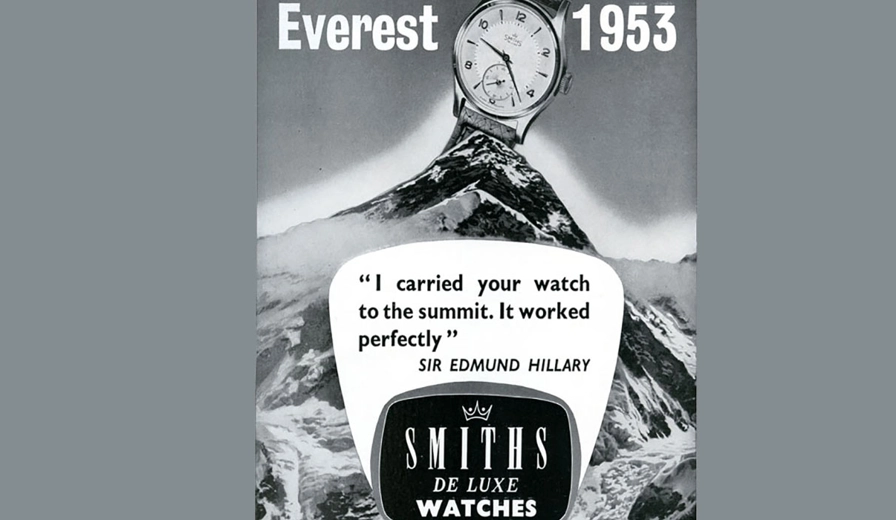

1953

Edmund Hillary completes the first successful ascent of Everest wearing a Smiths De Luxe watch, resulting in Smiths famous “Everest” watch range.

1958

Smiths innovates with the invention of a safe medical ultrasound device to produce clear images of human organs and unborn babies.

1967

Smiths innovates with the development of the first ATM, including PIN technology.

1978

Smiths works with customer Boeing to provide auto-throttles for the 727 and 737 ranges, and engine indicators for the 747.

1991

Smiths provides the electrical load management system for the innovative new Boeing 777.

1994

Smiths becomes the first company to introduce Computed Tomography (CT) X-ray explosive detection systems for hold luggage in the aviation market, revolutionising security at public airports.

1995

Smiths joins the FTSE 100 index on the London Stock Exchange for the first time.

2000

Smiths Industries changes the name of the business to Smiths Group plc.

2017

Smiths completes the purchase of Morpho Detection, and integrates the business into Smiths Detection, creating a clear market leader.

2019

Smiths Interconnect’s products are part of NASA’s successful Orion test flight proving Orion could pull astronauts to safety in the event of an emergency during launch.

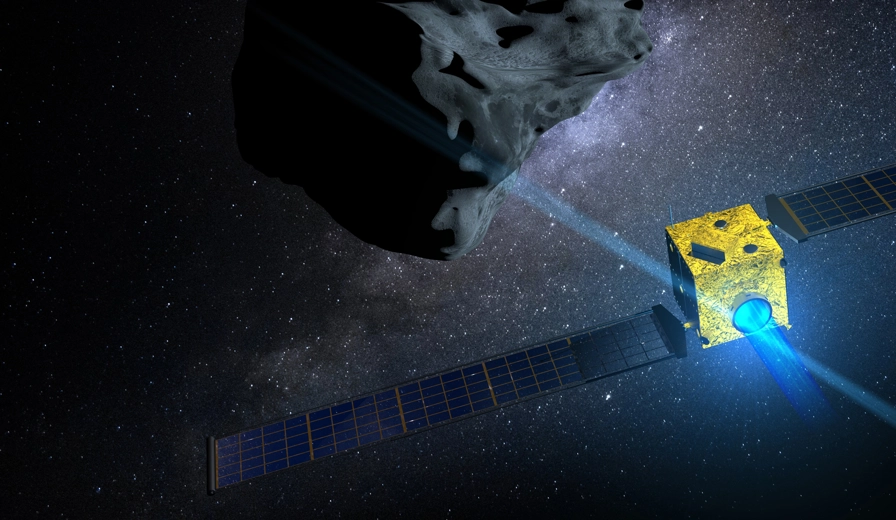

2022

Smiths Interconnect’s products are part of NASA’s successful DART mission, the world’s first-ever mission dedicated to investigating and demonstrating asteroid deflection by changing an asteroid’s motion in space through kinetic impact.

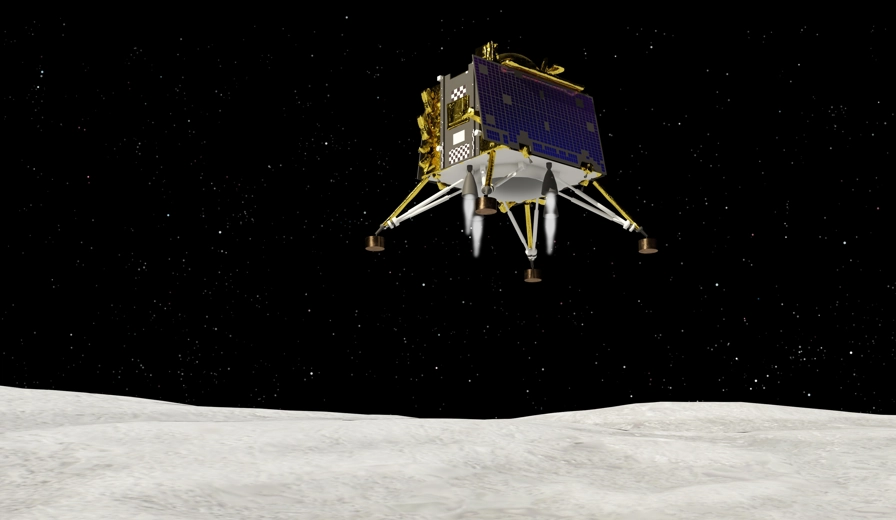

2023

Smiths Interconnect supports the Indian Space Research Organisation as it becomes the first country in the world to land a spacecraft successfully near the South Pole of the Moon.

2024

Smiths ground breaking 3D CT Scanners continue to be installed across major airports in the UK and globally, meaning travellers no longer have to remove liquids and laptops from their luggage.

Today

Today Smiths has c.15,000 colleagues in over 50 countries, and sells to over 200 countries and territories around the world.

Ongoing innovation for continued progress

To maintain our impressive innovation track record, we focus on both the development of new solutions and their commercialisation.

Together they are the primary drivers of unlocking enhanced value creation for the company and our stakeholders and are key to our innovation story.

This enables us to have a significant impact on the world around us.

- Smiths Detection equipment is used in over 90% of the world’s top 100 airports

- Smiths Interconnect technology is used in three-quarters of all geo-stationary satellites launched in the US and Europe

- Nearly 80% of all carbon dioxide injected underground uses John Crane sealing technologies

- Flex-Tek products are used in heating and cooling systems in 50% of the homes in North America

A global leader in engineering innovation

RD&E spend as a % of sales in FY2025

Patents (granted and pending)

% of revenue delivered by products launched in the last 5 years

project opportunities being pursued by John Crane in new energy, including CCUS, hydrogen and biofuels

Introduced AI and machine learning products into Smiths Detection

Innovation is central to Smiths Group’s purpose of engineering a better future. New product innovation is contributing meaningfully to our record growth: AI, machine learning and other digital technologies are central to this.

Introducing a new era in threat detection - X-ray Diffraction

Smiths Detection has launched a groundbreaking X-ray Diffraction technology scanner. This new technology represents the culmination of years of continued commitment to R&D and innovation – and that reflects our purpose to make the world a safer place. Watch to find out more.

Watch videoInnovation in action

Every Smiths product, service and solution is the result of innovation by our teams of experts – often done in collaboration with our customers and key partners to ensure it is commercially focused and solving a customer or end-user need.

Some of our focus areas include incorporating digital capabilities into our dry gas seals, introducing AI and machine learning into our detection capabilities, teaming up with partners to innovate around the future of green steel, and building the next generation of ruggedised connectors to help improve satellite technology in outer space. Read more below...

iCMORE

At Smiths Detection, our object recognition software, iCMORE, uses AI and advanced machine learning algorithms to reduce the burden on operators – and potential errors – by automating the detection process for suspicious items within inspected cargo, baggage or palleted goods. This innovation helps create a safer world, a more streamlined experience for travellers and a more efficient process for operators.

Smiths Detection has put together a global development team of data scientists, PhD scholars, researchers and software engineers to grow its AI capabilities, and is also building partnerships with key academic research institutes.

Innovating to reduce CO₂ emissions

Our innovations are contributing to the crucial transition away from a carbon-based economy, working with partners to create cutting-edge technologies at scale to improve the world.

Our partner, Midrex, is the industry leader in Direct Reduced Iron technology and is building the world’s first commercial green steel operation using 100% hydrogen direct reduced iron (DRI). This will reduce CO₂ emissions by up to 95% compared to traditional steelmaking: since replacing coal with green hydrogen created and heated by renewable electricity means that water - rather than CO₂ – and heat become the primary emissions.

Tutco SureHeat, a business that sits within our Flex-Tek division, has a multi-year agreement with Midrex to provide the critical heating element of the system, providing the technology innovation to heat the hydrogen using electricity - a key role in this process which has the potential to change the world’s steel manufacturing footprint through a path to green re-industrialisation.

Enhancing global connectivity and broadband

Smiths Interconnect operates at the cutting edge of the space, defence and communications industries. Its highly engineered components play a crucial role in helping improve connectivity for millions of people. It recently released a series of high frequency products that enable excellent satellite communications.

These products are designed for demanding applications where reliable performance and durability is critical. Our products are designed to solve customers’ problems through highly customised solutions where unique design challenges may be present, for example operating in the harshest of space environments. The products push the boundaries of size, weight and power, expanding Smiths Interconnect’s offering for the space, defence and communication industries.

John Crane Sense®

John Crane created an industry-first, sensor-enabled dry gas seal. These mechanical seals are typically used in harsh working environments and are crucial to the safe and efficient conveyance of industrial gas compression processes.

The innovative sensor-enabled seal provides important visibility into the health of the seal, giving customers confidence in their compressor reliability and paving the way towards predictive analytics. The digital technology helps to improve asset performance and maintenance schedules, as well as reduce unplanned downtime and the costs of repair.

Watch video