27 September 2024

Throughout FY2024, Smiths Detection introduced innovations to improve the energy efficiency of its products and manufacturing practices, and accelerated its established recycling and refurbishment programme to further reduce emissions and natural resource consumption.

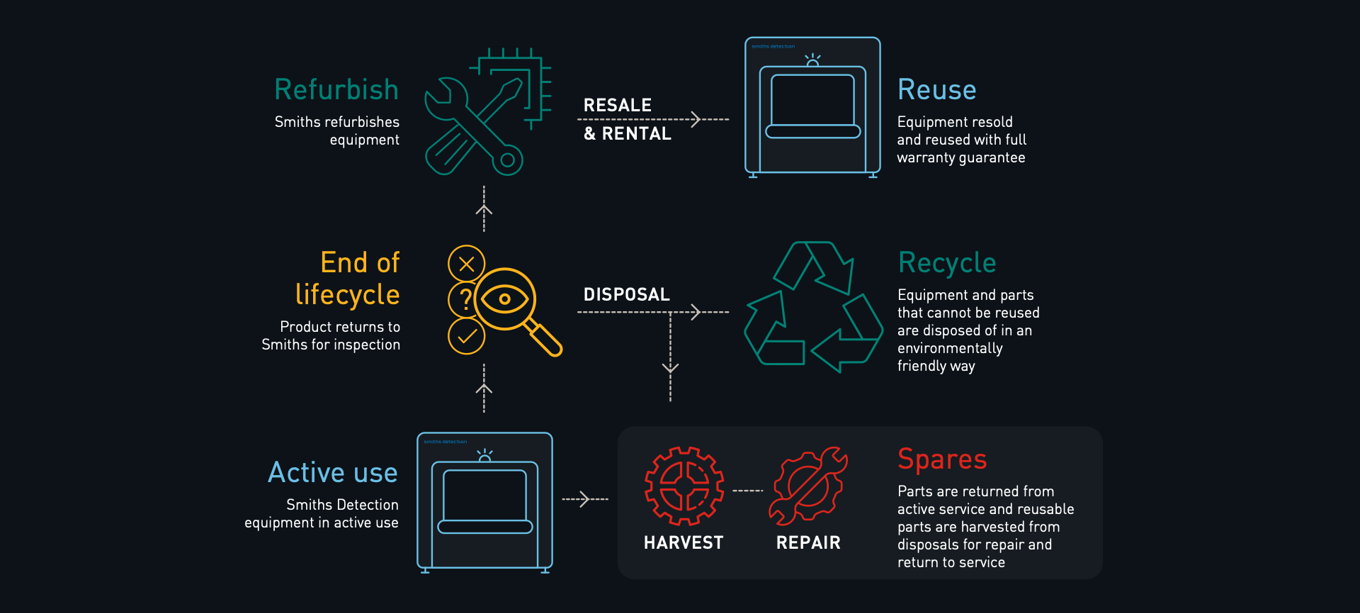

This programme incorporates three activity streams:

Component repair and reuse

Where practical, reusable components are returned from the field by engineers and repaired or refurbished and verified for reuse.

To encourage adoption of this practice, our standard service contracts are moving to explicitly include the use of refurbished parts unless requested otherwise.

In FY2024, this policy saw more than 9,000 reworked parts return to active service, which represents savings of 1,137 tonnes of CO2e Scope 3 emissions – a 22% increase on FY2023.

Unit refurbishment and repurpose

When customers no longer require a unit, Smiths Detection seeks to retrieve it so that we can refurbish then resell or rent out to new customers.

One high-profile example is when we supplied the 2022 Commonwealth Games in Birmingham with a high-spec fleet of 147 screening units that had previously been used by one of our US customers. This not only proved that refurbished equipment isn’t a compromise on security, but also saved 181 tonnes of CO2e compared to the commissioning of new equipment.

In FY2024, we sold over 260 refurbished units, saving 323 tonnes of CO2e Scope 3 emissions.

Parts harvesting and recycling

As well as introducing an intensive waste management programme to divert our own site waste from landfill, Smiths Detection has established a complete decommissioning and disposal service for systems that have reached the end of their functional life.

Any parts or materials that can be repurposed are harvested, and repaired or prepared as appropriate for resale and reuse in service, which helps to conserve valuable resources and extend equipment life.

The rest is responsibly disposed of in strict compliance with local and global regulations - including for lead, radiation sources and other hazardous materials, and the Waste Electrical and Electronic Equipment (WEEE) Directive. Our robust data management plans ensures that, when requested, all sensitive information is securely removed from systems before disposal to prevent the risk of data breaches.

In FY2024, Smiths Detection decommissioned and disposed of over 500 pieces of equipment.

With strong customer uptake of these and other initiatives , Smiths Detection is continuing to invest in circular economy efforts that will help both our organisation and our customers to further lower emissions, reduce the consumption of natural resources and contribution to landfill, improve supply chain security, and drive cost efficiencies.

We remain committed to reducing our emissions and natural resource consumption, and will continue to accelerate this work in FY2025 and beyond.

Kini Pathmanathan is Group Head of Smiths Excellence & Sustainability

We remain committed to reducing our emissions and natural resource consumption, and will continue to accelerate this work in FY2025 and beyond.

Related blogs

Engineering the future: Why successful apprenticeships are a team effort

Find out more

Insights from European Hydrogen Week

Find out more

World Cancer Day - Katherine's Story

Find out more