24 November 2023

After fur, fuel and finance, Edmonton is now progressing to the next frontier - clean energy.

Since its earliest days as a Hudson Bay Company trading post, Edmonton in Alberta has retained a pioneering spirit. By the 1940s, fur had given way to fossil fuels as the commodity of choice, and it had established a new identity as the ‘Oil Capital of Canada’. From these beginnings, financial, research and educational sectors emerged and flourished.

But now it is forging towards its bravest – and arguably most important – economic frontier yet: blue hydrogen. At the heart of its mission is the £955 million ($1.6 billion CAD) Alberta Net-Zero Hydrogen Energy Complex, which is already well underway with construction due to be completed by 2024.

And the world is watching.

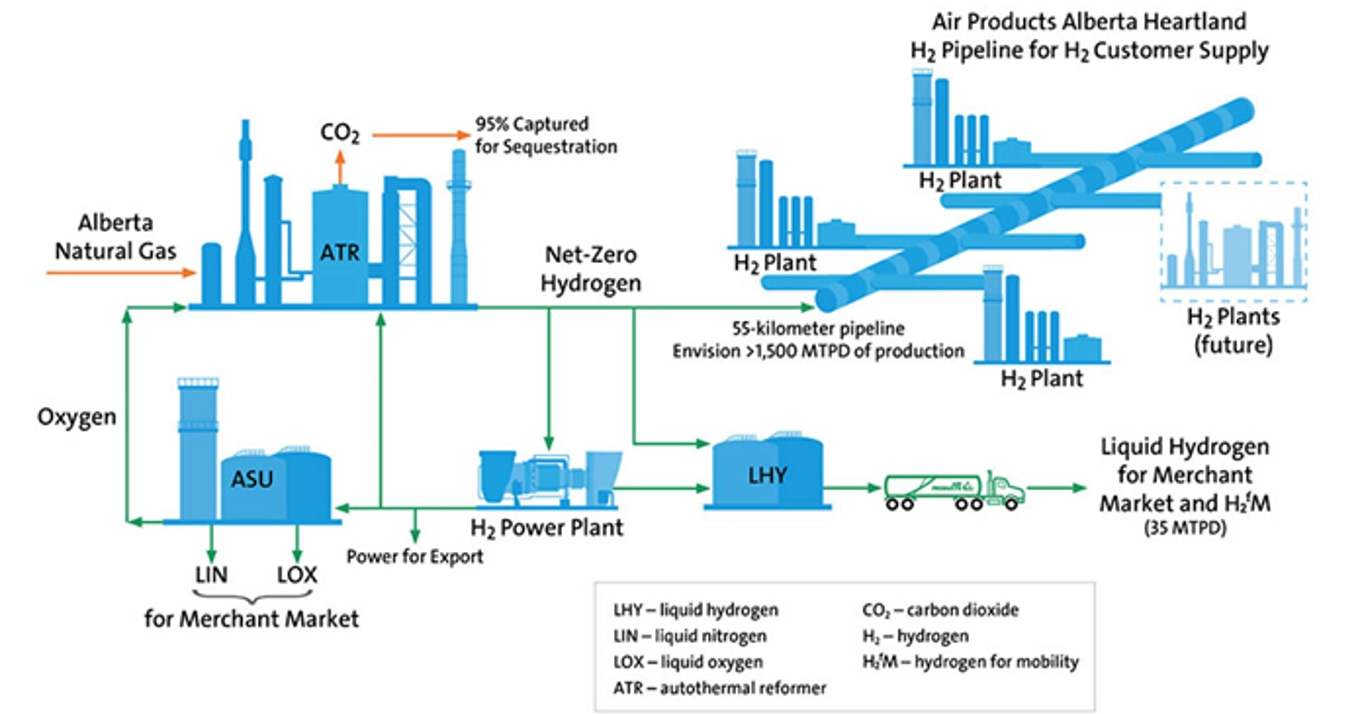

That’s because, whilst it is not seeking to offer ‘green hydrogen’ with carbon-free power and production, it does promise to sequester more than 95% of the CO2 emissions from the hydrogen production process to deliver what is called ‘blue hydrogen’.

Its success will demonstrate the feasibility of a low carbon step-change that’s widely implementable by industry this decade. And when the International Energy Agency estimates that clean hydrogen demand could reach 115 million tonnes by 2030 - well below the 200 million tonnes needed by 2030 to be on track for Net Zero emissions by 2050 – that accelerated deliverability is planet-critical.

Key to the realisation of blue hydrogen’s low carbon promise is an advanced design using innovative technology.

At the heart of the Alberta facility are centrifugal turbo compressors and pumps. The quality of their seals and couplings is vital for optimising their performance and minimising carbon leaks, and the compressor supplier chose John Crane’s products due to our well-proven record in other mission critical applications, as well as our network of local service experts.

To date, we’ve secured a contract to supply the site with 16 dry gas seals (DGS) for these compressors; four high-performance H Series couplings to connect the compressors to the electrical motor; six gas and oil filters to ensure the proper quality of seal gas and lube oil; and at least 18 mechanical seals and systems for the critical pumps.

Once fully operational, the complex is expected to be capable of producing over 1,500 tonnes of hydrogen per day with 30 tonnes per day of liquified hydrogen produced at a separate plant on the site.

As well as intending the hydrogen be used in a broad range of industrial and mobility applications, it will be used to generate enough clean electricity to power the entire facility. Upwards of 95% of its carbon emissions will be captured (which could amount to more than three million tonnes per year at peak operation) and additional clean electricity will be exported to the grid to offset the remaining 5% of emissions.

As an integral part of Alberta’s existing hydrogen network - with three world-scale production facilities and a 55km pipeline delivery network – the complex is envisioned as a key facilitator of cleaner operations by major refining and petrochemical customers across the Alberta Industrial Heartland.

Imagine the impact it would have on greenhouse gas emissions – and the attainment of Net Zero 2050 - if all major industrial areas followed suit.

It would bring the frontier a lot closer.

Related insights

Searching for E.T.

Read our latest Engineering Explained insight on Smiths Interconnect's role in NASA’s Europa Clipper - to search for life on the fourth largest of Jupiter’s 95 moons.

Find out more

Integrating a sustainable ethos into our products

Find out more

How our engineers are helping hydrogen to become a source of new energy

Read our latest Engineering Explained insight piece on how our engineers are helping hydrogen to become a safe, secure and profitable source of new energy

Find out more